Supplier digitization in supply chain

Digitize trade – it is important

Trade flows and supply chains are largely paper-based.

There is a simple way to get 100% digital supply chain visibility and to digitize all the trade documents involved - suppliers can deliver digitization of supply chain documents easily with the right technology.

Paper-based supply chains and trade documents lead to significant costs, risks, friction. McKinsey estimates that the cost of paper-based trade processes to the global economy is in $billions (see their analysis here).

Suppliers have all the trade paperwork even though it may come from many sources. Suppliers can easily digitize the paperwork.

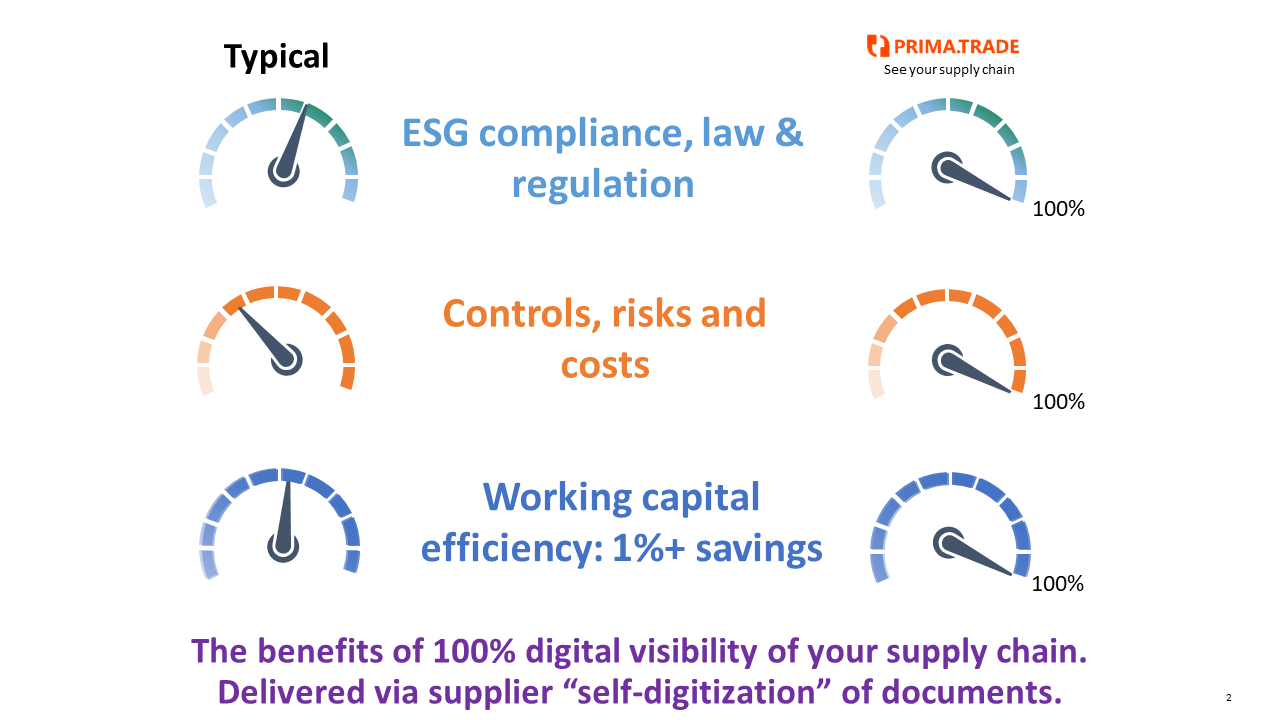

The digital supply chain and 100% visibility of trade flows deliver many benefits:

working capital optimisation and significant savings on spend

smoother and quicker clearance of goods through customs

reliable cash forecasting

significant organisational savings for both buyers and their suppliers

and more

What does supplier digitization of the supply chain look like?

A digitised supply chain involves taking all of the many types of paperwork that flow from supplier and service providers (eg: logistics) to the buyer and making those documents available as both scan copies and structured data.

Typical fields that can be pulled from the different documents in a supply chain include:

the different dates when things are happening (order, shipment, invoice, delivery, payment),

descriptions of products,

transport methods and carriers,

vessel / truck / airplane / rail IDs and container IDs,

loading and delivery locations,

numbers of pieces being shipped,

numbers of packages involved,

unit prices for different products,

which purchase orders are being included,

the total value and amount due,

ESG data on the source and composition of products

and so on.

In a digitised supply chain, all documents are digitised and all the data is pulled off the documents and organised in a structured way.

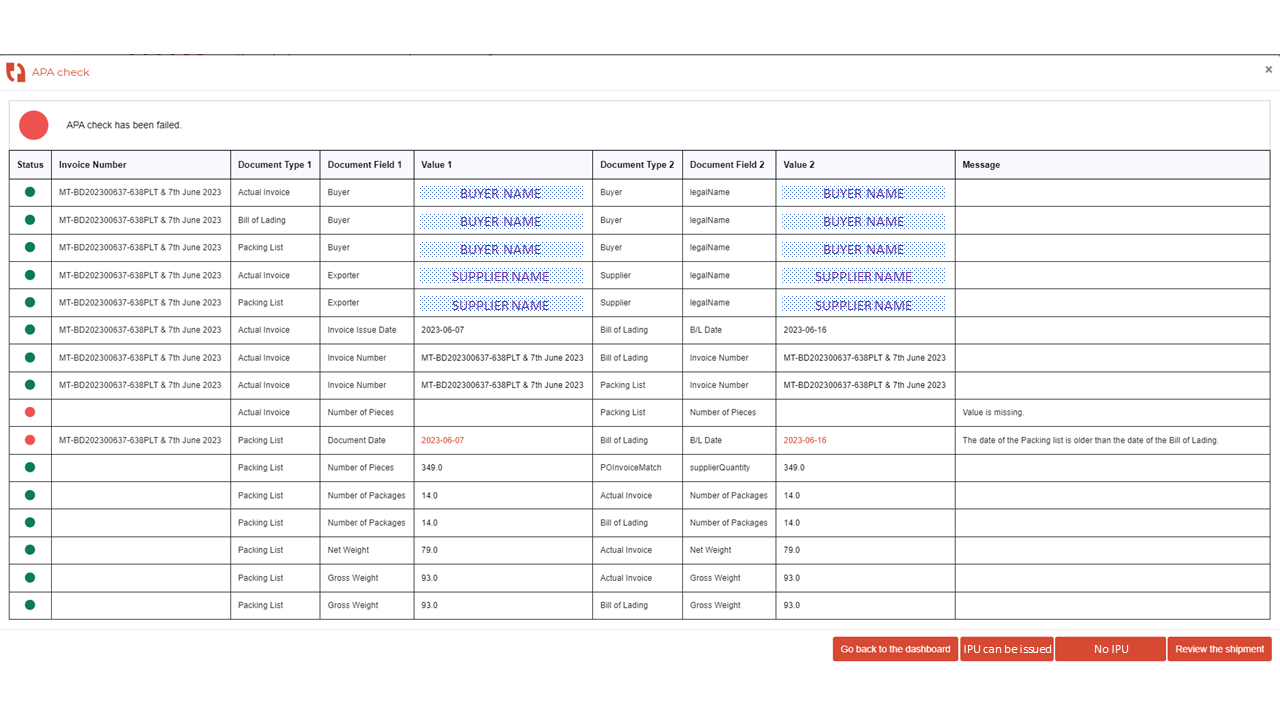

This supports comprehensive reporting and allows cross-matching of data across the documents to validate that everything is reasonable and makes sense.

Is it difficult for suppliers to digitize supply chain documents?

A well-designed system can achieve this result quite easily via "self-digitization" - the supplier does the digitization of all the required supply chain documents at shipment.

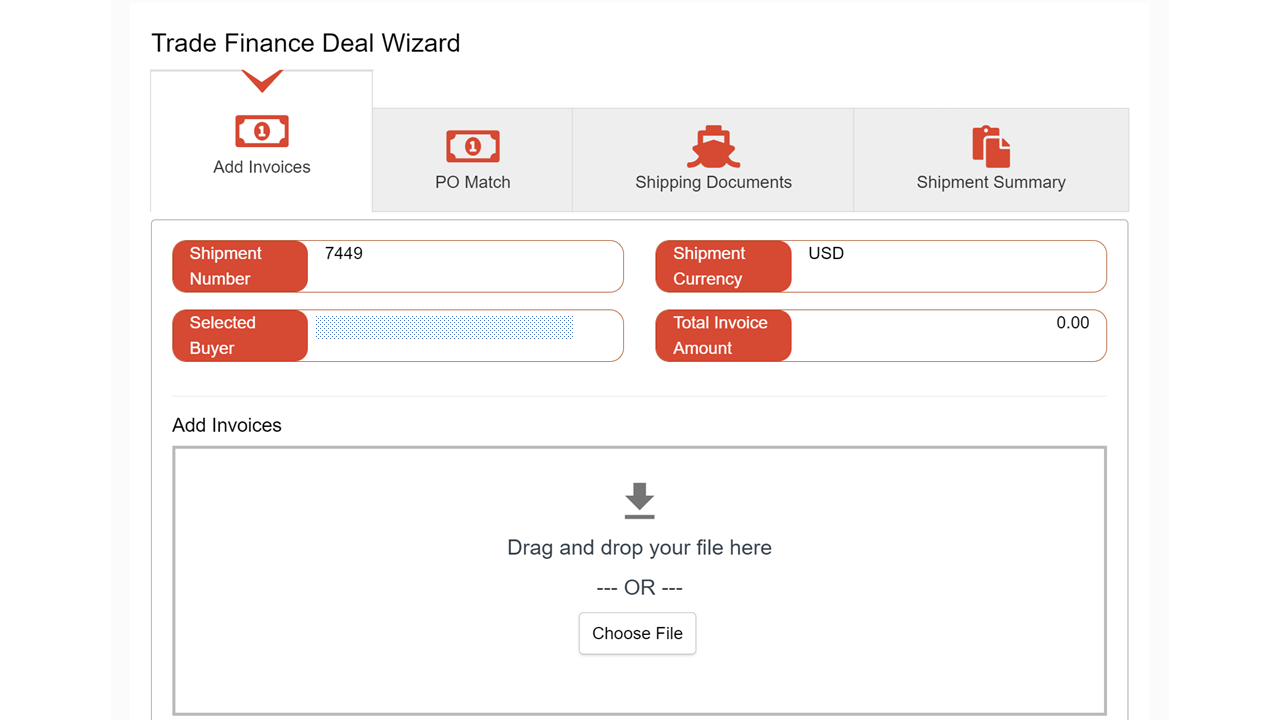

Drag and drop - a simple four step "wizard" to digitize all the documents

See more on how our platform works here.

The necessary capabilities are:

A secure multi-party portal that connects buyers (importers) and suppliers (exporters) together

An easy way for buyers to define what documents and data they want

A good user interface that steers the supplier simply through the process

A strong OCR capability which can accept the many different types of documents and different formats involved, quickly and accurately pulling data off the document images into a structured and useful format

A flexible supplier journey, understanding that not all trade documents may be available immediately; paperwork should be allowed to progress digitally as soon as documents become available without waiting for a complete package - so suppliers and buyers can both return to shipments to add and digitise more paperwork as it becomes available over time.

What trade documents are involved?

Our platform (PrimaTrade) handles all the documents involved in cross-border trade, including:

Commercial invoices

Transport documents (BL, AWB, CMR etc)

Packing lists

Certificates (origin, compliance, materials etc)

Sourcing and supplier maps

Inspection reports (FDA etc.)

Other document types can be added easily

How does the buyer control the document list?

There are three levels:

Supplier-level

Shipment-level

Product-level

Buyers say what documents that want and the platform automatically creates a list for each shipment.

At the first level (supplier), some documents are requested because of the supplier identity (eg: given this country and this supplier, we need X, Y and Z documents).

The second level is the shipment – so typically a commercial invoice, packing list and transport document – potentially with a certificate of origin.

The third level is the product. This is where compliance paperwork is typically handled, for example:

This product needs this certificate,

That product needs this inspection report

These products need evidence to support the source of materials etc.

ESG compliance requirements are making this area much more complicated. For example, modern slavery legislation nowadays requires proof of source to evidence that materials are not coming from locations where forced labour is being used; advertising standards regulations also require documentary support for any ESG or sustainability product claims.

So any platform supporting trade digitisation has to be able to cope with these additional requirements – and to build the list of required documents for a given shipment taking the individual product level into account.

Product level ESG documents – seriously?

Indeed yes – as regulators tighten the rules to implement modern slavery legislation and to require advertisers to support any sustainability or ESG claims – it is essential to collect documents that support and reference individual SKUs or purchase orders (ie: collections of a particular product) - see PrimaESG, the module of our platform that addresses this requirement.

For example, a simple t-shirt might require:

Supply chain / sourcing map: this shows the supply chain (all the tiers naming all the suppliers) involved in growing the cotton, spinning the fabric, dyeing and processing the fabric, cutting, making and packing the T-shirt. The purpose is to evidence where all elements of the product have been made to show that no forced labour was involved.

Organic cotton certificate: if the T-shirt is claimed to be made from organic cotton, then a certificate is required showing that the cotton sourced for the t-shirt fabric has been sourced from an organic supplier. The purpose is to support this claim in the advertising of the product.

Material composition: if the t-shirt is going to be claimed to be sustainable, then the level of circularity in its materials and its potential for recycling has to be evidenced, usually this is done by an inspection at the supplier by a suitable firm that produces a certificate which then references the specific product.

Making this work is important

Digitizing trade is an important initiative supported by the ICC (see the digitial trade initiative here), by the DCSA (see here) and pretty much universally across regulators, participants, industry, carriers and so on. The digital supply chain is coming – in fact, with PrimaTrade, it is here now.

Suppliers are on our platform every day, at scale and around the world , using our carefully-designed screens, powerful OCR and rules engines to self-digitize all their trade documents as they ship.

It is quick and simple. It takes about 15 or 20 minutes to process an entire shipment across the full set of paperwork – leading to an accurate, reliable and a fully-digital picture of the shipment and its products. And this is a lot less time for suppliers than typically happens today over email via multiple communication channels with different departments on the buyer-side.

This works as a process – and saves considerable time for suppliers who otherwise are responding via multiple communication channels to multiple importer departments in order to provide the required documents.

Benefits flow immediately

The benefits emerging from this process are immediate.

Automatic and system-based management of documentation and data.

Automatic and real-time cross-checking to verify that appropriate documents are provided; and this benefits both buyers and suppliers because it helps suppliers to get their paperwork right.

And automatic linking of paperwork to payment – ensuring that suppliers who get their paperwork sorted out efficiently can get their invoices automatically approved in real-time and can then be paid very quickly.

Our technology can automatically compare and match fields across different digitized documents to arrive at an automated decision on invoice approval at shipment.

Automatically cross-check each field (value 1) with other documents and data (value 2)

Is this difficult to set up?

Amazingly, this technology is very easy to set up. Our platform is implemented “over-the-top” so it can go live without an initial IT project. Simply set up the rules to ask for the documents that you want, switch on the suppliers, data flows, automation follows.

Many clients find a benefit in linking our platform up to a purchase order feed to help with specifying what documents are needed and to have the supplier also match the shipment to purchase orders as part of the process. This enables an automated and secure 3-way match to be done at shipment (POs to transport documents to invoices).

What next?

The supplier self-digitization model pioneered by PrimaTrade is being freely shared in the market.

Contact us here (info@prima.trade) or talk to your advisers about how to join the digital revolution in supply chains.